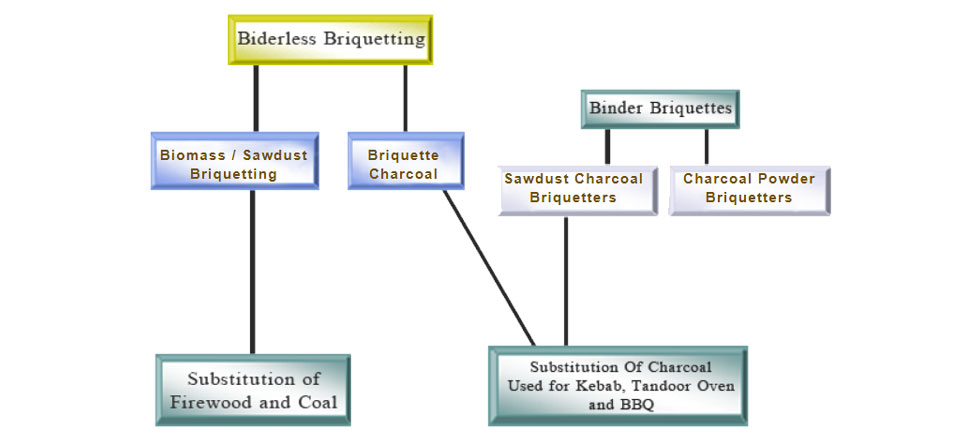

Briquetting Technologies : Biomass / Sawdust Briquettes

Bio-Mass Briquettes – These are made out of the any bio mass using the following processes and they are the substitute for fire wood or steam coal used in the boilers or Room heating where there will be high flame

- Drying of raw materials to less than 15% moisture content(flash drier)

- Hammer mill grinding to make uniform sizing

- Briquetting

Either using Screw type extruder machine or

Using Ram type (die and punch ) machine.

In this process no binders are used, and yield will be 100% of dried raw materials

Briquetting Technologies : Briquette Charcoal

Briquette charcoal --- These are made out of the biomass briquettes by using Carbonizing kilns mostly and preferably the screw extruded briquettes with Central hole. These briquettes are substitute for charcoal for the barbeque, kebabs and tandoor ovens where there is only red hot and no high flame. The processes involved are as follows.

- Carbonizing using batch type kilns

- Cooling the carbonized briquettes.

In this process no binders are used, and the yield will be approximately 30% of extruded briquettes . Shapes may be cylindrical/square/hexoganal

Briquetting Technologies : Charcoal Briquettes

CHARCOAL BRIQUETTES --- these are made from bio mass. These briquettes are the substitute for charcoal for the barbeque, kebabs and tandoor ovens where there is only red hot heat and no high flame.

- Drying of raw materials to less than 5% moisture content. (flash drier)

- Carbonizing the powdery raw material contact for the technology ---- adam + partnerindustrial design + appropriate technology consulting for renewable energy applicatication of the "adam-retort" for more environmentally friendly carbonization of biomass.P.O.Box 50108, Addis Abeba, ETHIOPIA www.biocoal.org

- Mixing process --- the above charred raw material is mixed thoroughly with water , binder and fillers .

- Briquetting process --- the above mixture is briquetted into the shapes of oval (Almond) , square pillow using roller presses.

- Drying process-- The above formed briquettes are dried using sun drying , tunnel drier or batch type oven drier

- Cooling process --- The dried briquettes are cooled on a conveyorised belt drier if tunnel drier is adopted In this process Binders are used, and the yield will be 25% of dried bio mass.

Briquetting Technologies : Charcoal Powder Briquettes

Wood charcoal briquetting -- These are made mostly from the chunks/ dust small waste charcoal from vendor sale depot. Or bush (kiln site).

These briquettes are substitute for charcoal for the barbeque, kebabs and tandoor ovens where there is only red hot and no high flame.

- Preparation of the available charcoal powder – sieving, pulverizing the chunks/ lumps

- Preparation of binder – gelatinizing process or chemical

- Mixing process- mixing the binders and fillers

- Briquetting process- oval shaped, square pillow.

- Drying process – sun drying or automated TUNNEL TYPE continuous or batch type

- Cooling process- if only continuous/ batch type is adopted

- Packing process- paper packing, gunny packing or carton packing

- Complete conveyors at all the stages – belt , screw and bucket elevators. In this process Binders are used, and the yield will be 100% of charcoal powder / chunks / waste pieces of charcoal .